I’ve been teaching sailing for 24 years full time and have been delivering boats for 15 years and unfortunately, I don’t get to do things how I have learned they should be done very often. This was a wonderful exception. I was first contacted by the owners of this very new catamaran to help them sail their boat to Mexico. They wanted the boat in Mexico because they were retiring and Mexico would be their first adventure and winter abroad and if it went well they would sail to the South Pacific the following year. I told them about the differences between delivery and training saying that delivery was best done with a crew I selected but that training would take them further. We understood each other and they said they would like the focus on training. I said I could oblige and asked who their crew was going to be to which they said they had some family and friends in mind. I asked which of them were the best sailors and unfortunately, they admitted none were sailors. I pointed out that it is important to be a sailor to be counted as crew and that they should cultivate some relationships with the potential crew to help them on future passages. So they said they did have a friend who was particularly keen but only had crewing experience on racing rowboats. That’s a start I told them. Enthusiasm and respect for the elements is a perfect foundation for any aspiring mariner. So I advised that this person join some cruise and learn courses offered in the area or better yet break up the classes into weekend courses on boats appropriate to the cert level. Unfortunately, the classes were very full in the area at that notice so we decided to run a cruise and learn for them on Tula and it would serve as a review for the rest of the sailors. This worked out very well. We took some of the pressure off the certs and more focus on learning the boat. These days spent cruising the San Juans in the spring provided everyone myself included a great sense of what the boat could do. It turned out to be a windy week and we saw 40+ knots at one point.

After this educational cruise, we planned to meet for a 106 or Advance Coastal Cruising Class on the boat where we planned to take the boat out to sea and get to know the boat in the ocean before the jump down the coast.

Doing crew overboard drills on ocean swell is a great exercise and always creates huge development in boat handling and cooperation. These big cats are made to be short-handed so everything is led to one place at the helm which can be good solo and short-handing but as soon as you want to put a person on each job to do tight maneuvers like this you start seeing some of the limits of the design and this of coarse is part of why we must do it. The practice and review with new crew of these drills is essential for being able to both get back to a person in the water and how to maneuver the boat in a tight spot under sail if you have to pick up a mooring ball under sail or sail back to the dock if you loose power.

Stowing on multihulls is something to get used to.

Tattoosh off the port bow. Southing next!

Going soft with this sort of treatment.

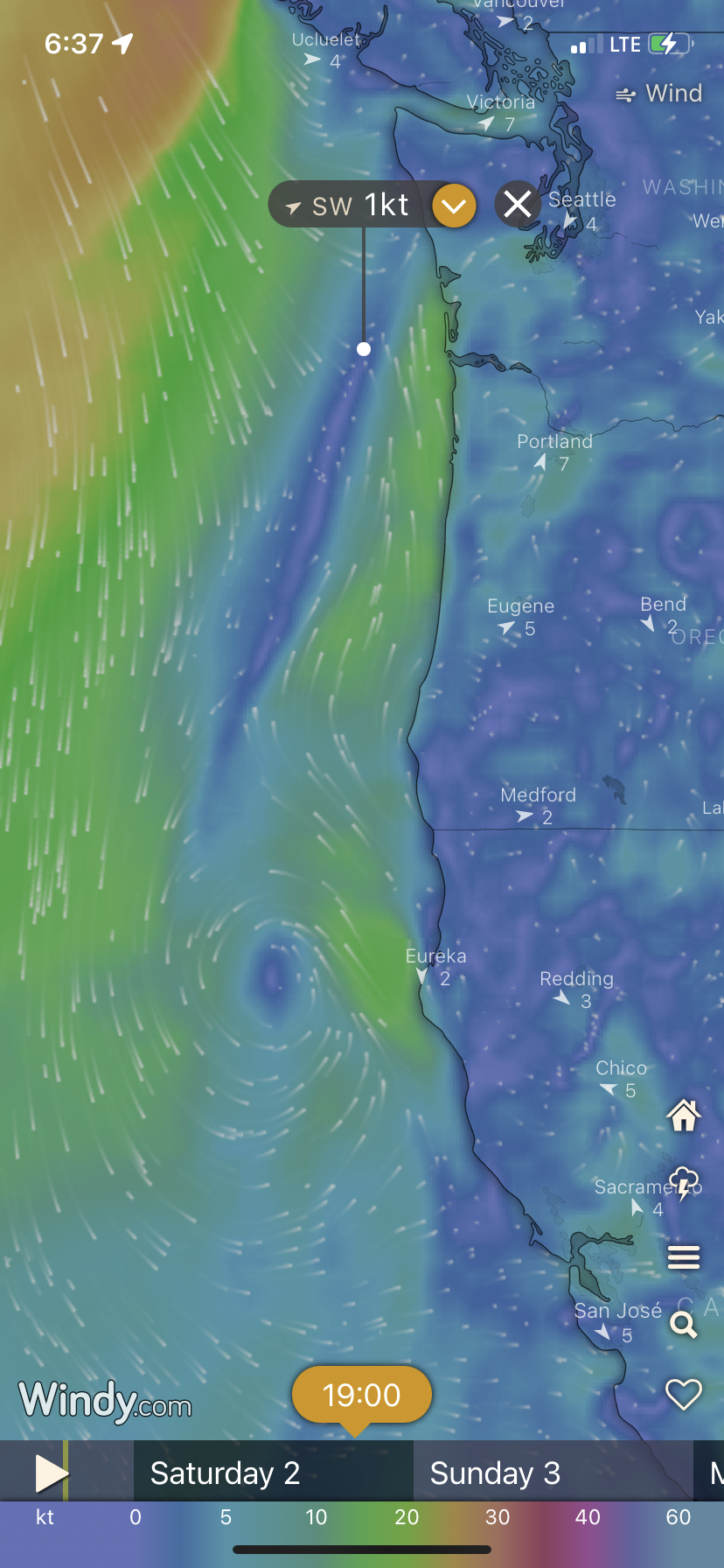

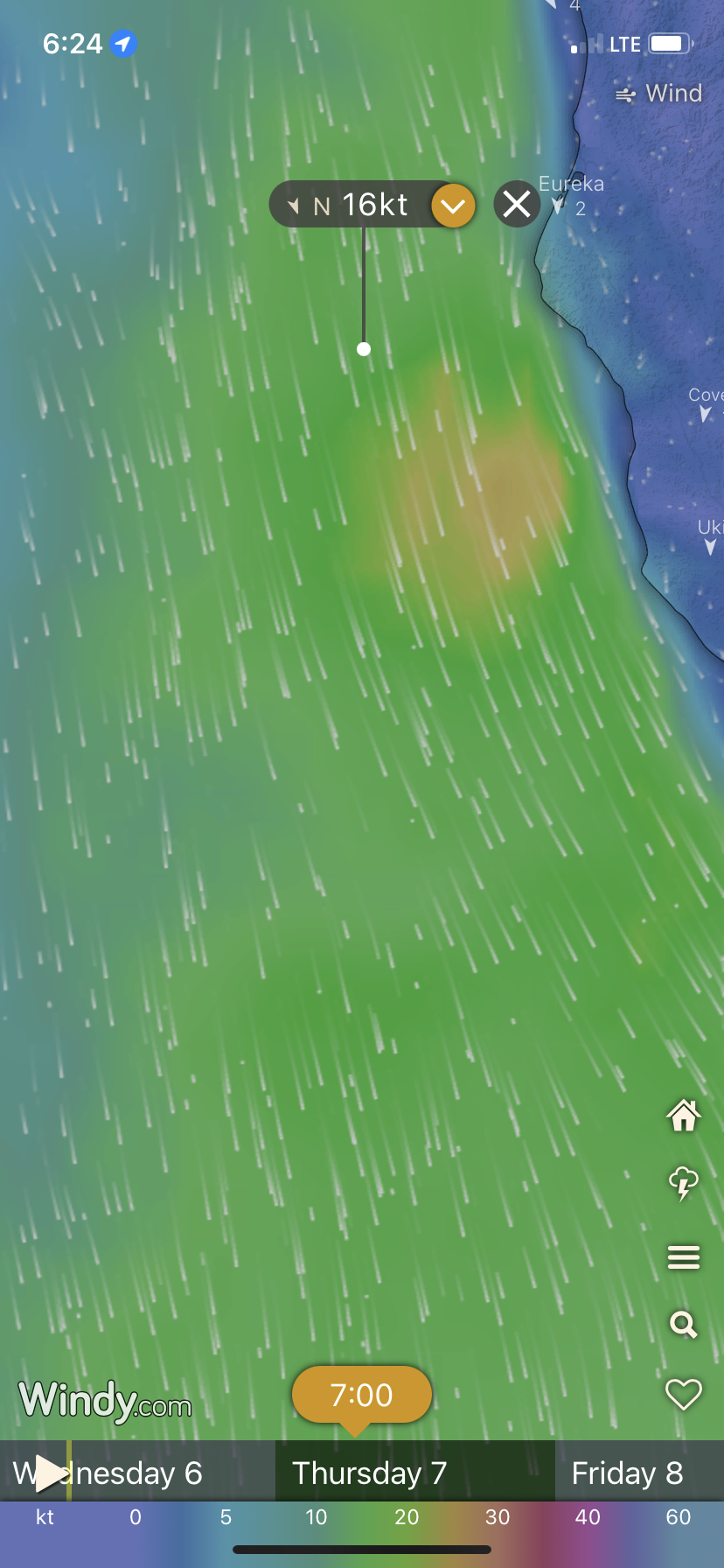

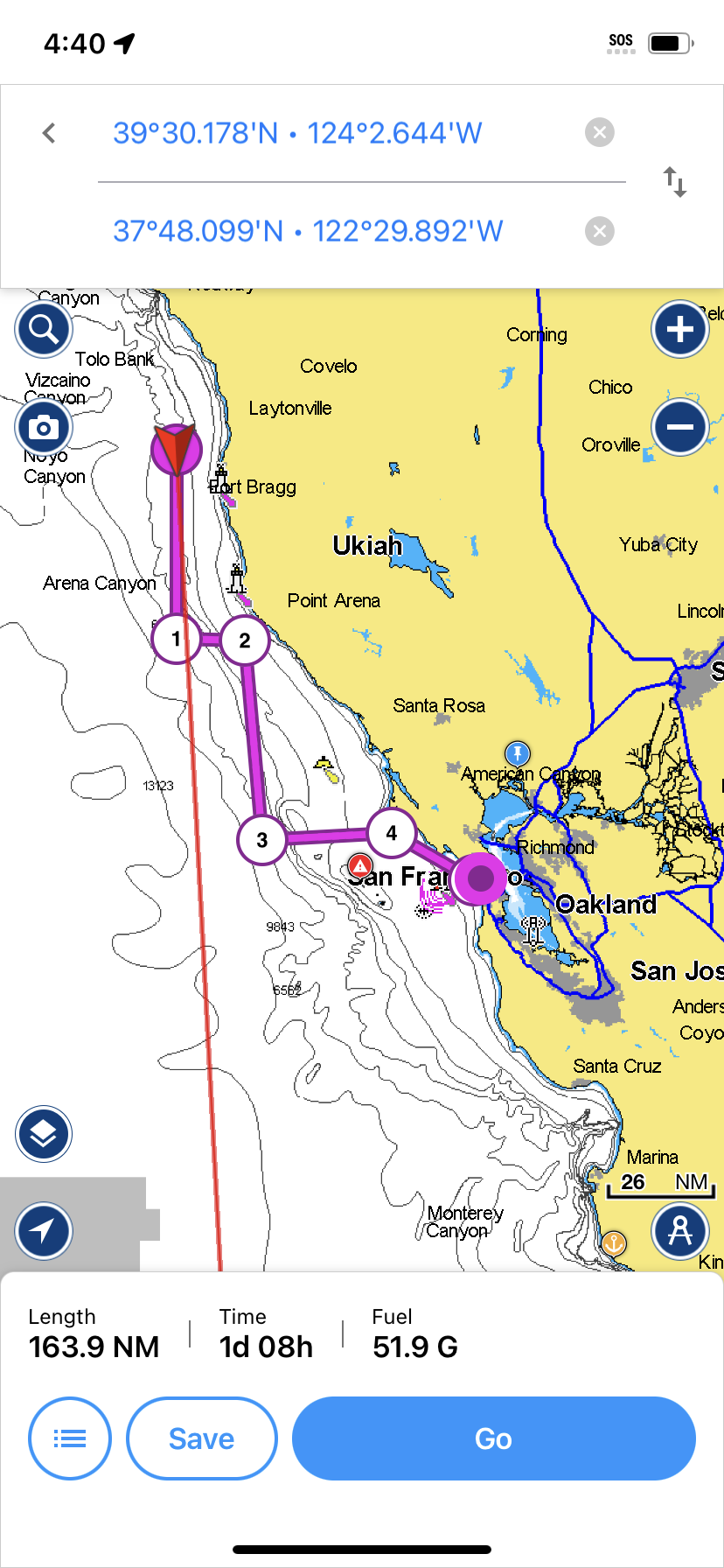

We departed in settled weather and did a last fuel-up at Neah Bay. The forecast called for some 15 knots offshore so we added some Westerly into our southerly heading and did eventually find some wind. I could see it wouldn’t be enough as it was right behind us and would have required lots of jibes and a slow VMG. (velocity made good: basically the shortest distance between two points is a straight line). I could see the crew wanted to hoist and try it out so I briefly explained and acquiesced realizing it was a good way to make my point and earn some credibility for future calls. A two-part main halyard is tied to the top of the mast and runs down through the shackle at the top of the main and back up and over a sheave on the masthead. This means you have to pull twice as much halyard but it’s half the load. My biggest concern was coming from the dead reckoning I was doing on the capes further south. It was looking like if we kept the vmg at 6 we could make it in one shot. Fuel was less an issue than most boats as they had added a hundred-gallon tank.

Regular engine checks are key to successful passage making and I included it in the standing orders and watch log for the end of the watch to check the engines. This does require a keen eye as some of the mechanical problems can be hard to see before they are catastrophic.

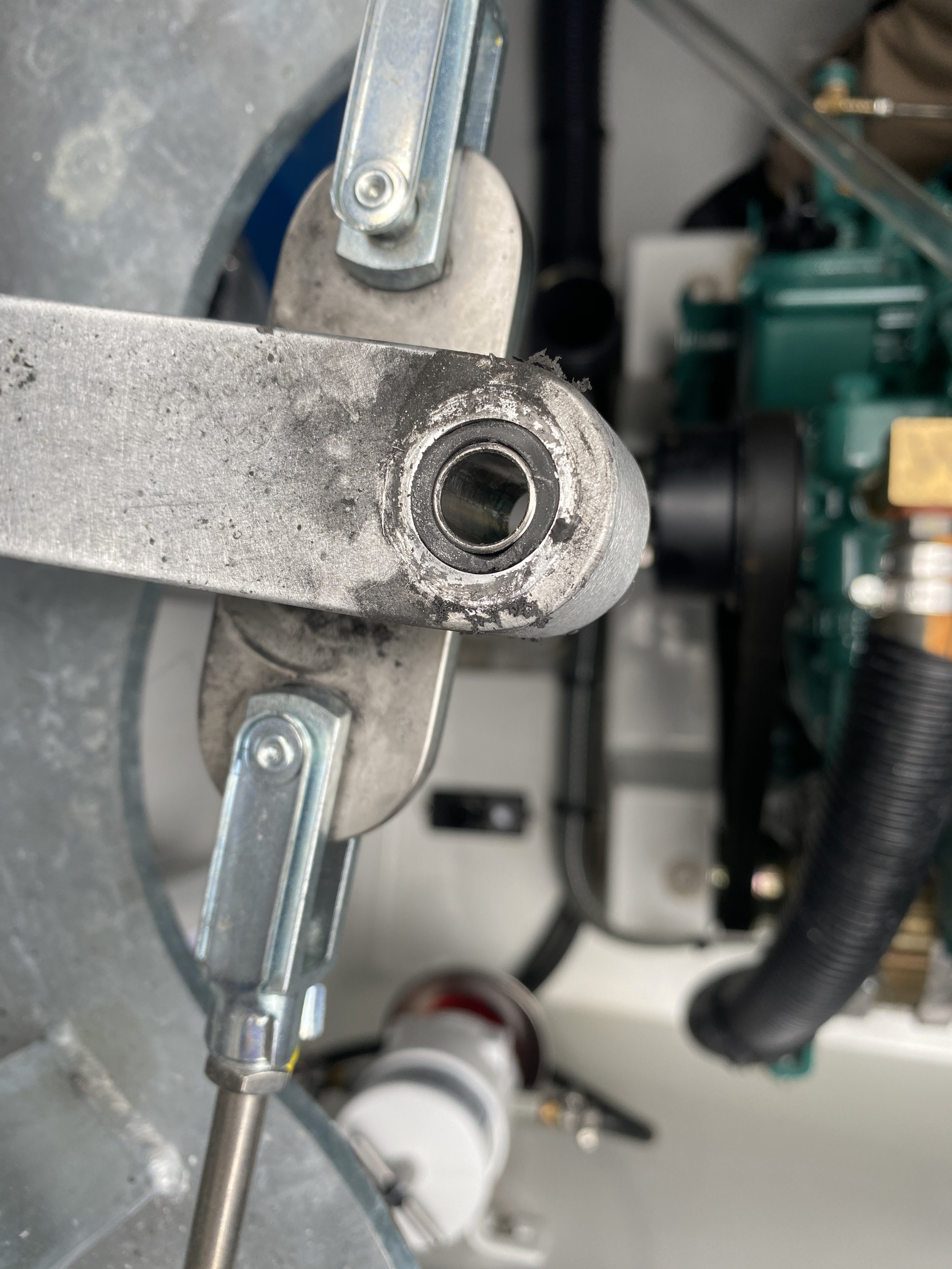

It was on one of these checks that I noticed the bar that connects the two rudders was torquing with the loads of the waves and the autopilot.

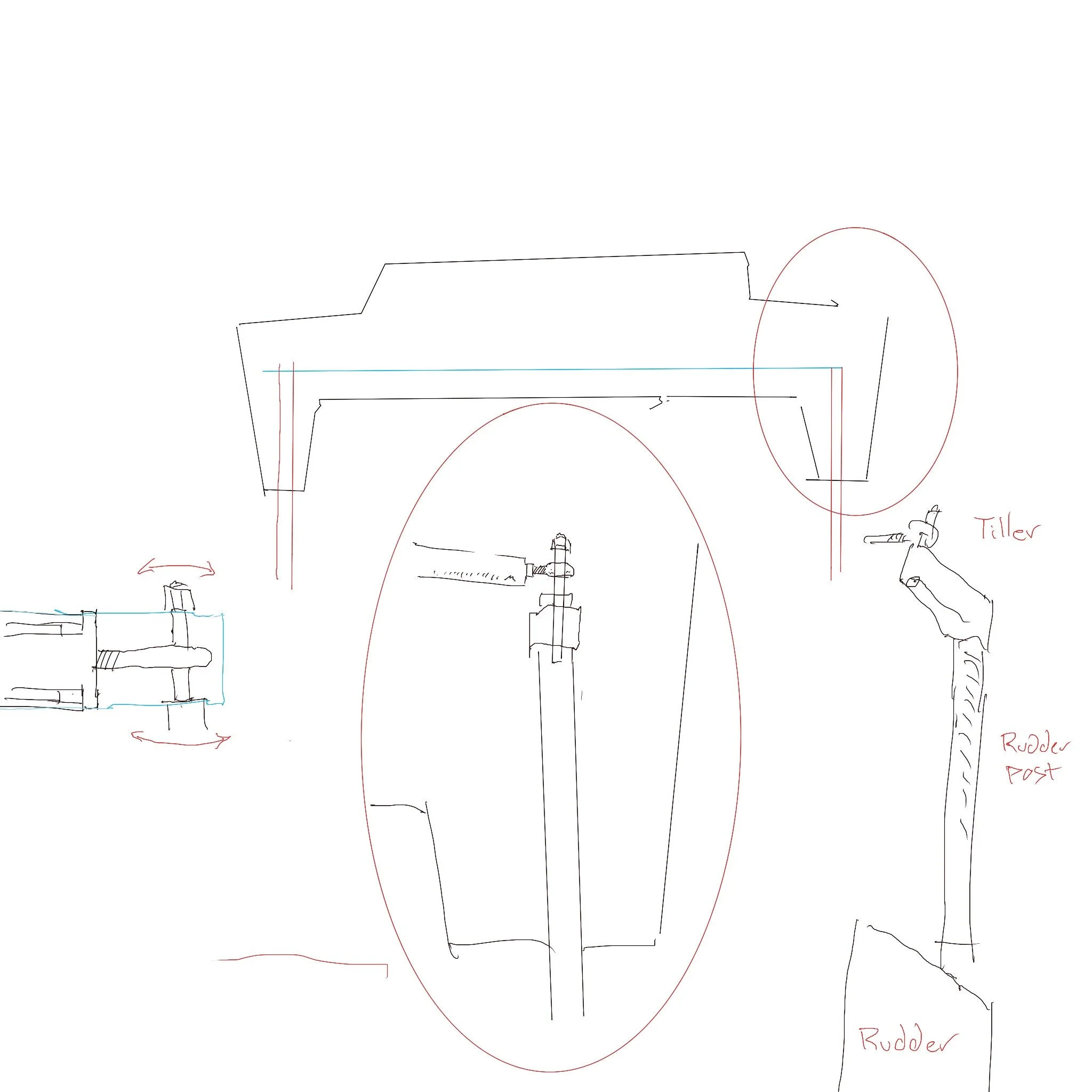

I brought it to everyone’s attention and learned that prior to leaving and after much research before buying the boat. They decided that the stock design was not good enough and hired a local machinist to add some hien joints. Unfortunately, they used the existing hardware as well and it was torquing the rubber bushing and this was causing concern as once it wore through the rubber it would gall the aluminum tiller end.

We made the call to go into Newport and a friend brought some materials to make new temp bushings.

To prevent ongoing boat repairs and compounding failures at sea, I have included a clause in my delivery contract stating that repairs during a passage will cost more than those made beforehand. This financial incentive encourages boat owners to complete repairs before the journey starts.

In this case, I guided the owners in the repairs while we added two lay days. Fortunately, this looked like it would not cause too much issue with weather routing.

Special delivery of hard to find materials and cookies and in a TCYC bag no less. Day saved.

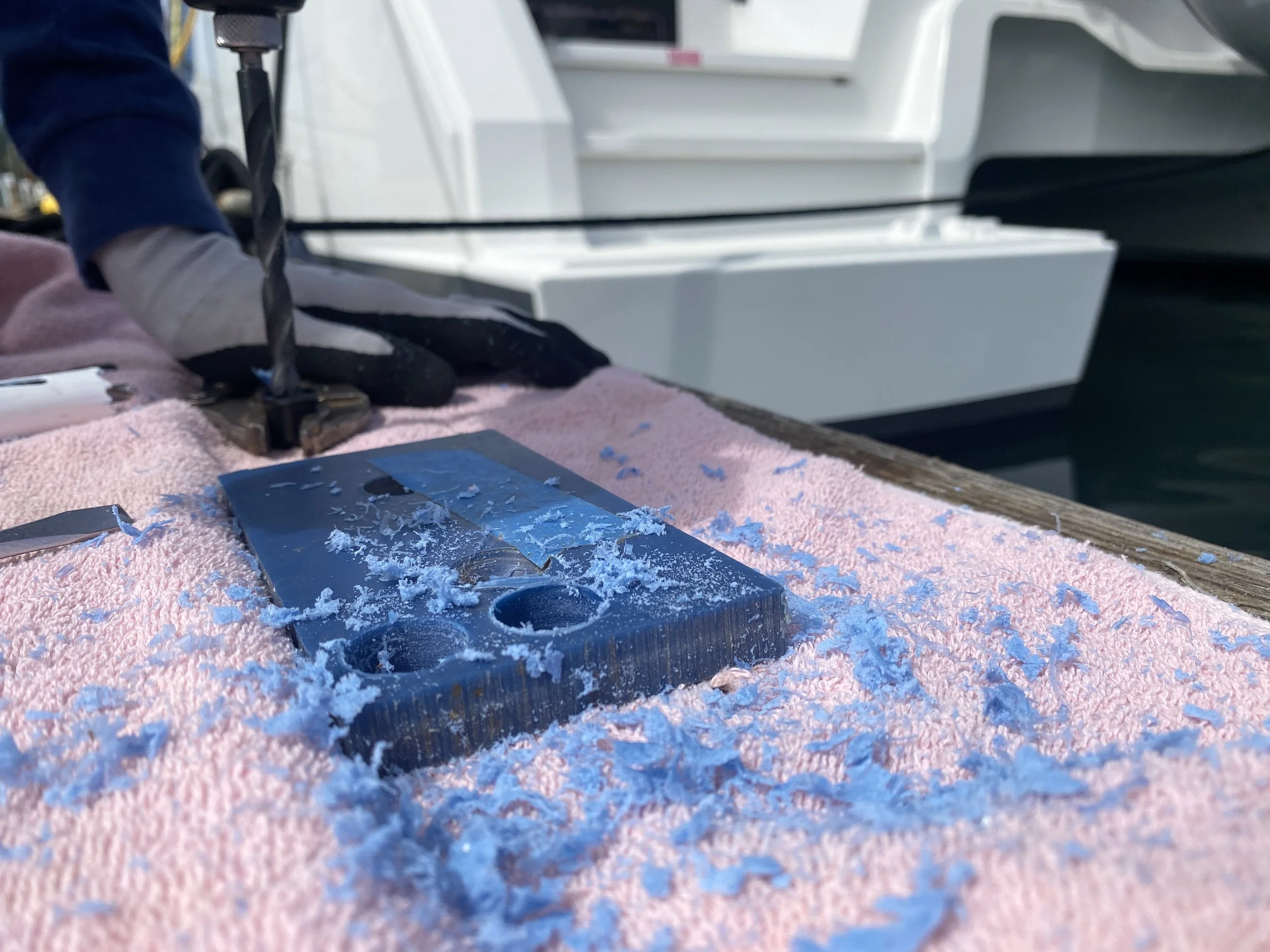

While in Newport Oregon the friendly fuel dock attendant let us use the grinder wheel in the back shop. While doing this work we managed the fend off most of the Coho Hoho rally boaters strolling the docks with the beers looking to distract our progress and perhaps get a tour of the boat.

I warned the crew that these seem to be opportunities to glean what they can from others about weather routing advising them that they should try and qualify any information with the sailor’s vessel and experience.

One boat had the dinghy lashed over the jack lines on the bow. One boat didn’t have fenders down at the dock and the one boat owner, most interested in looking at Tula because he had an older FP admitted he his starboard engine had discharged all its oil into the bilige.

Sunrise off the Oregon Coast

You can see the rubber coming out of the bottom of the tiller here and note the pin for the steering cable is about to come out.

yikes

retrofit heim joint. I wonder if they had to mill that much off the end fitting….

Custom bearings out of HDPE

Two beautiful new bushings were milled and the steering was put back together and we were off again. There would be a little wind rounding the cape but were would miss the worst of it. Our approach to the gate would be in adverse current and in bad viability so we opted to anchor in Drakes Bay and enter the bay in the morning.

Night time “Shy Jibes”. (Tacking instead of jibing)

Being out of cell range has its advantages.

Anchored just out the gate in Drakes Bay waiting for a better tide in the morning.

Pretty momentous experience for this crew. Honored to be a part of it.

What a great trip and feeling of success. I feel confident that the Tulas will do well in their future adventures.