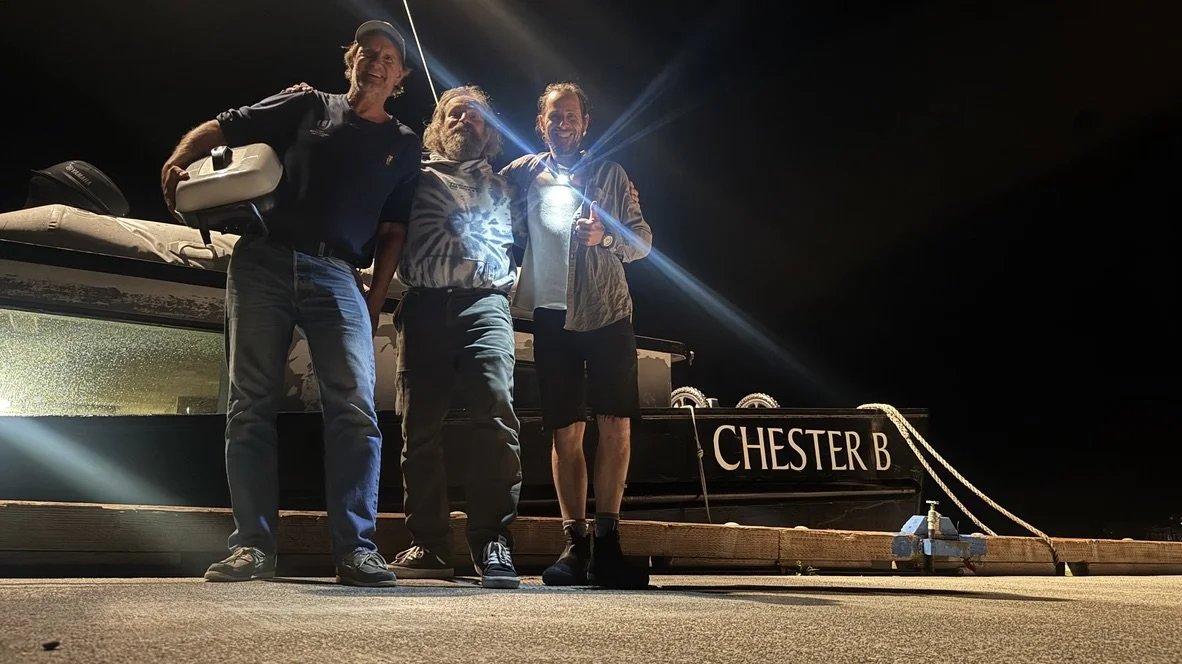

This was a wonderful passage with some great folks. I can’t always say that but this one was fun.

My friends at Ballard Sails mentioned they had a customer for whom they were building new sails, who would be a good candidate for GBA’s help. I reached out and was surprised to find that these blue water initiates were younger than me! It’s easy to understand why most of the folks who hire GBA are older, which makes it so refreshing to see some youngsters pursuing their bluewater dreams.

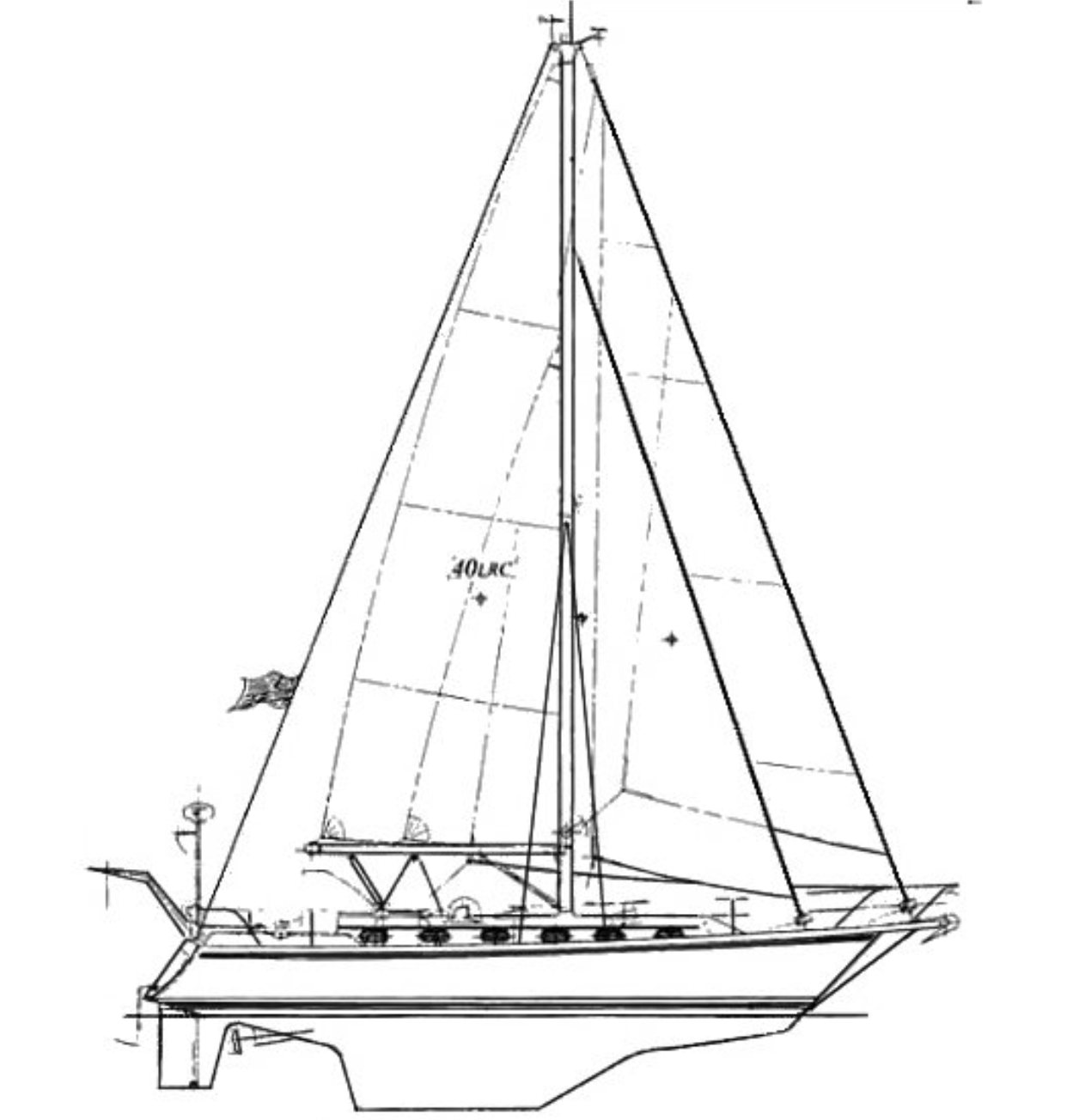

These folks were in the process of quitting their work and preparing their beautiful Caliber 40 to sail around the Pacific on a multi-year cruise. On a trip to Seattle, I asked to stop by the boat to see the project, and I was instantly impressed when i got to the boat. The boat was a bit of a mess due to projects and the highest quality black water hose was about to be used to replace the old, and there was what looked like 1000 watts of solar installed on and around a newer dodger enclosure. I didn’t need to see much more; I knew that these guys were doing it right. Before I left, I said that they might want to unplug from the dock and make sure the systems were working before casting off for Mexico. The response? It's already unplugged. The cord is for the drill.

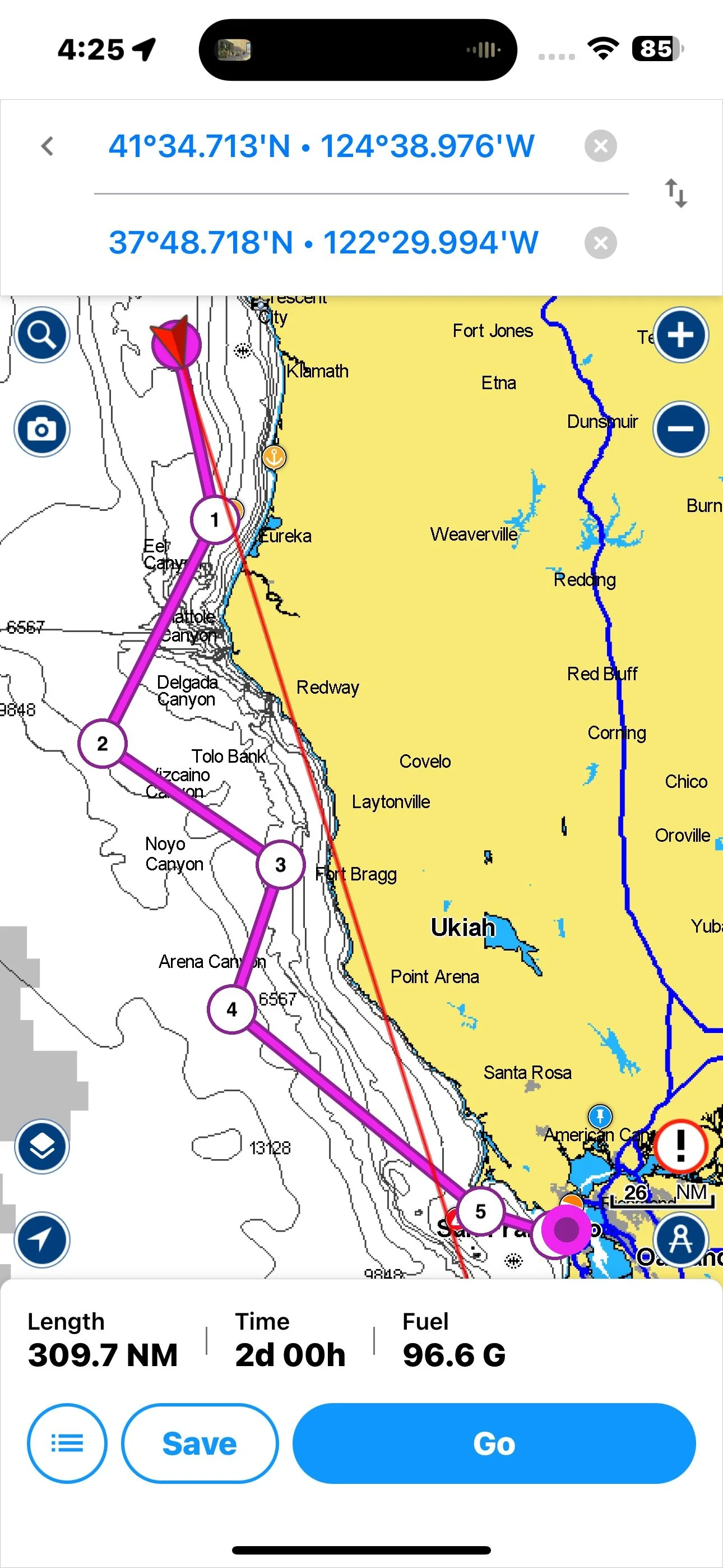

I was sold. We shore up the billing details and scheduled some Zoom calls, and I told them that I would find a fourth crew member to make the passage to SF in September.

To make things even better, my shipmate Tom Meester, who races with me on my boat, Elsewhere in the San Juans, was going to make it!

We were set, all I had to worry about was catching that tuna I promised Tom.

Fast forward, and I head down to the Port of Friday Harbor to meet them with my go bag rolling behind me. Tom arrives on a ferry from Orcas Island, and we are off.

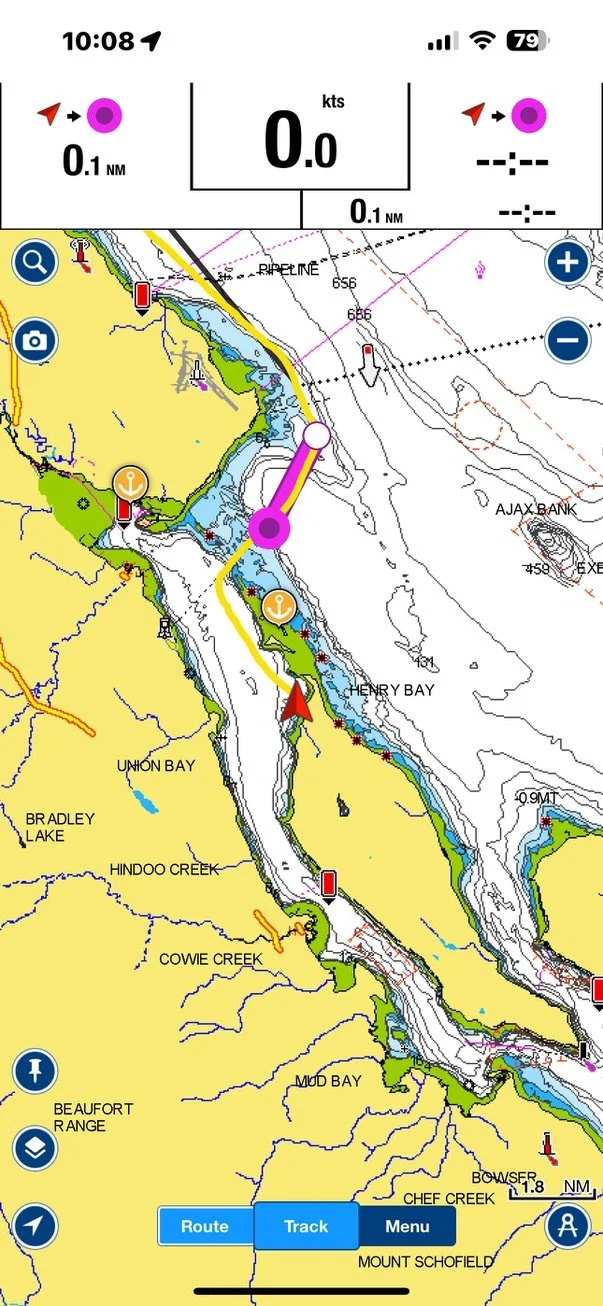

After we clear Cattle pass into the eastern straits the weather is a little bumpy (30+), and Nate is queasy and quiet (not a great sign), so we tuck into Port Angelies for one last shore meal.

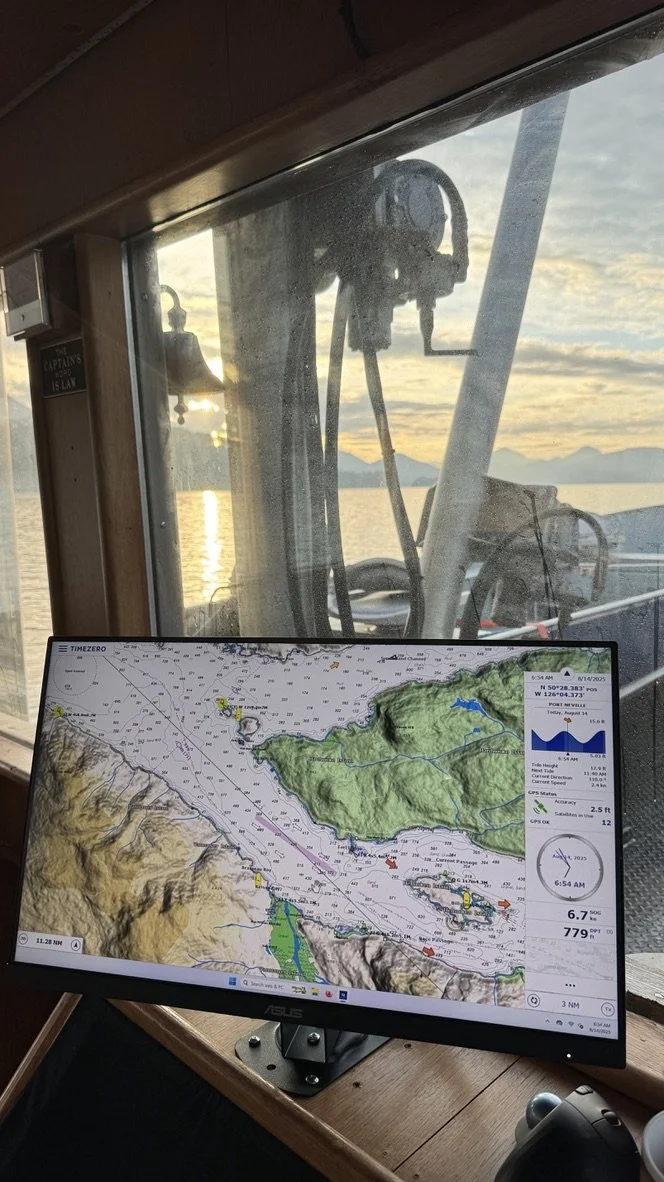

Fog most of the day and motoring. The engine is louder than usual. Yanmars, newer ones at least, run at higher rpm as I understand it, but are efficient and vibrate less than their predecessors and some competition. The noise is a product of sound deadening or the lack thereof in this situation.

This is where noise canceling headphones really help with the noise fatigue. I’ve put earplugs in under them before to double up. I used to bring shooting ear protection because they have tech that turns them on and off when there are loud sounds. I think all boats should have some muffs for engine checks, and all sailors should pack at least earplugs.

This is boat we heard on the radio talking to the CG about their damaged steering. Seen here under emergency tiller heading into Neah Bay.

Going in and out of fog with a fishing opener gives us some good practice in discussing how the radar works and how to negotiate this kind of traffic.

Day 2

More motoring and some motorsailing. The SUP rack mounts are catching the jibsheets on jibes. These and bikes on deck are a pet peeve. Some lashing is employed to cut down on these snags.

The furthest NW corner of the lower 48.

Day 3

Jesse is sick, but some dolphins cheer him up. Jesse and his wife Chelsea, are on a watch together, and she’s having to take up the slack, but she’s doing great. I’m monitoring the situation and preparing Tom for me taking Jesse on my watch if it gets rough. So glad to have Tom there. I’ve sailed with Tom for years and know he and I can handle the whole thing if it comes to it.

That afternoon, a strange thing happened. A fairly large bird landed, and that is generous way of describing what looked like as ungraceful a crash landing as possible into our bow pulpit. I have given many land birds rides that have been blown out to sea, but never a sea bird like this aside from a Sooty Petrel in forest fire smoke at night. The other strange thing was I couldn’t identify it. This strange bird sat on the pulpit for maybe as long as 10 hours. This was enough time using our Starlink to ask around and look at pictures online to get an ID. I sent a picture to my sister who is quite a birder and who lives in Estonia and she said it was an immature Red Footed Boobie. This couldn't be because we were way out of its habitat. Well thats what it was, and in our research, a friend of Chelsea’s, suggested that we could submit it to a bird watching site in Oregon and perhaps win bird of the month because of the rarity of the sighting.

Day 4

And the fish I've been praying for is in the boat. The only person not excited is Jesse. This is understandable because fish, especially tuna, have a fishy smell, and the only thing worse than diesel exhaust for someone teetering on the edge of puking their guts out is fishy smells.

Before all this, I had noticed a few “bait balls” on the horizion so I put a handline (what cruisers call a “meat hook”) in the water and was adjusting course to pass through these patches of disturbed water that the birds were clouding around.

Tom thought we ought to increase our chances with another line, and right after he put his line in my line, hooked a fish, then as I pulled it in, bang, Tom had one too! Unfortunately, my fish got off, and as he was pulling his fish in, I asked Chelsea if they had a bonker, and was blown away to be passed a brand new gaff! I got the fish in the cockpit and said my thanks, and we got about bleeding and cutting the fish into steaks. The only downside was that the fridge was full, and we were down one eater, so we had to cook some right away. Everyone got a chance to try their tuna recipes eventually, but Tom, who cooked first, blew everyone away right out the gate, and we had a wonderful lunch. Seasoned blackened tuna on rice and arugula. Did I mention Tom used to own a restaurant and is a chef?

It was so good that even our sick sailor started to perk up and decided to have some after the good smells got to him.

We could have kept fishing and I’m sure pulled out hundreds of pounds of fish because we just kept going through bait ball after bait ball.

Day 5

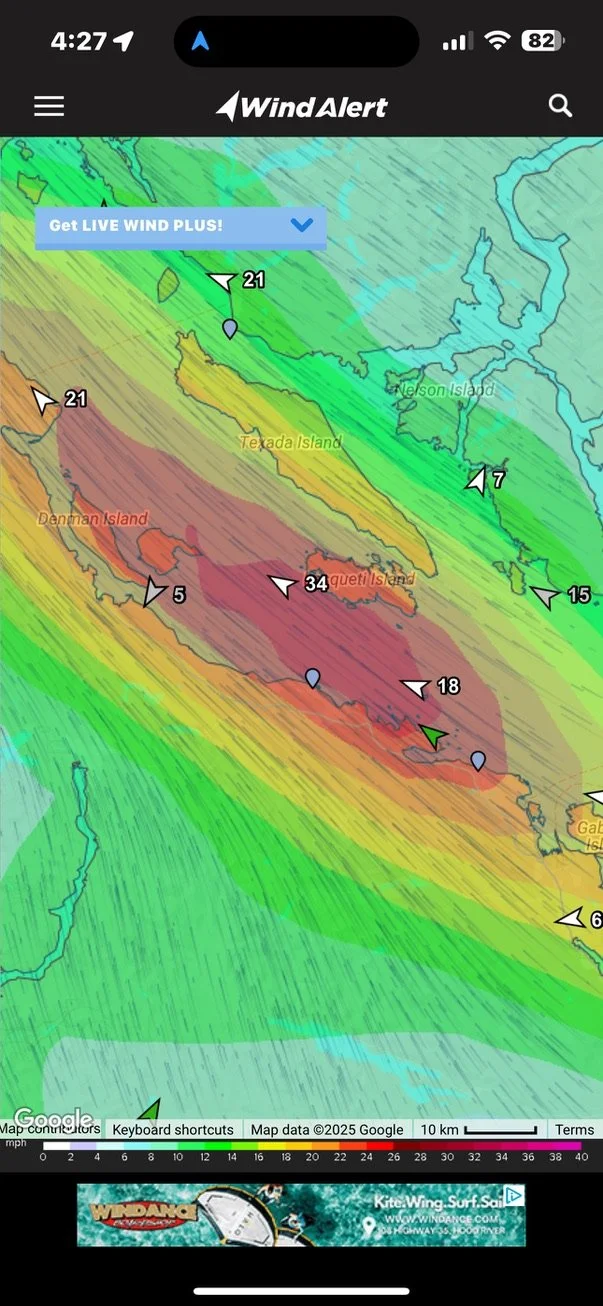

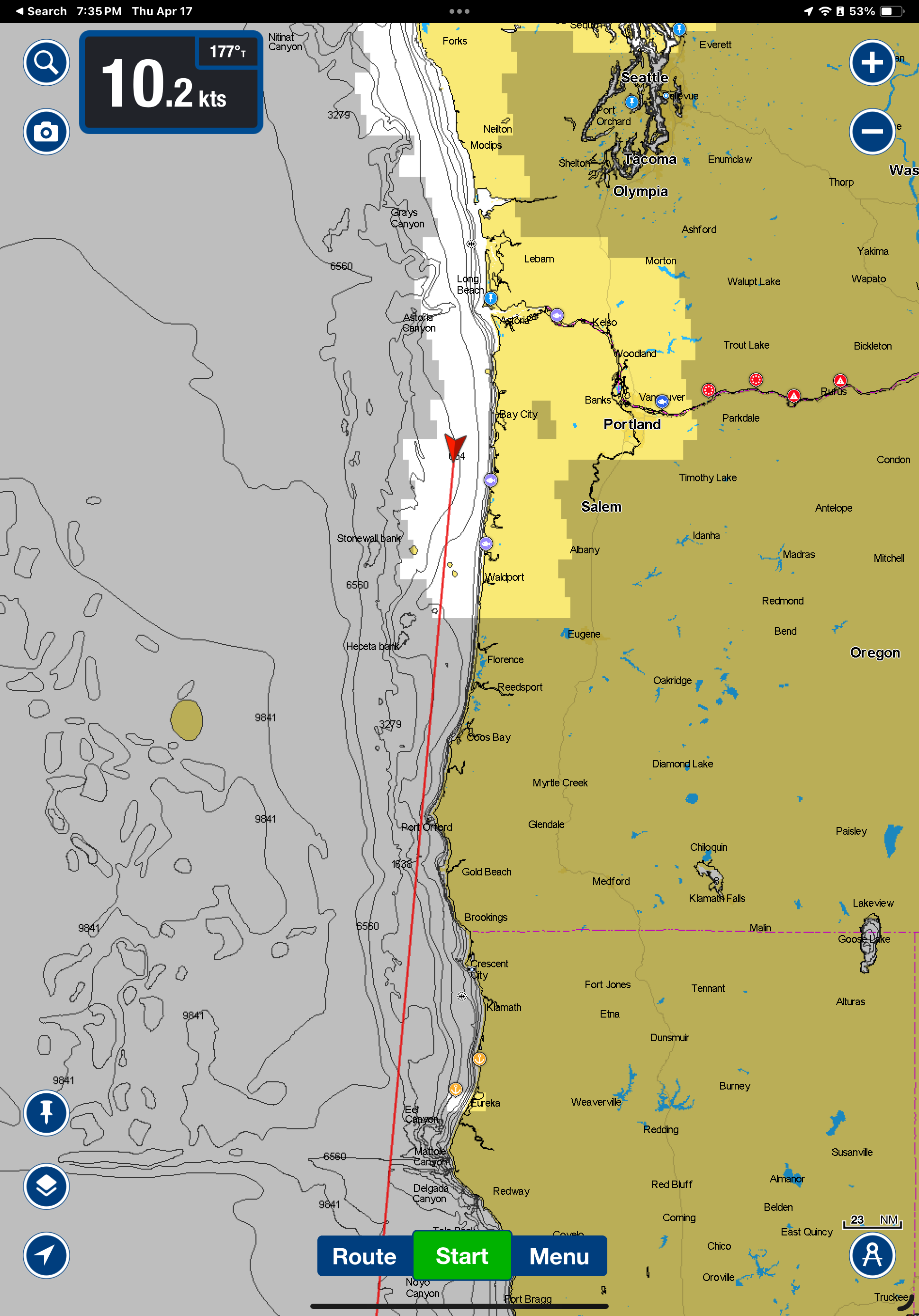

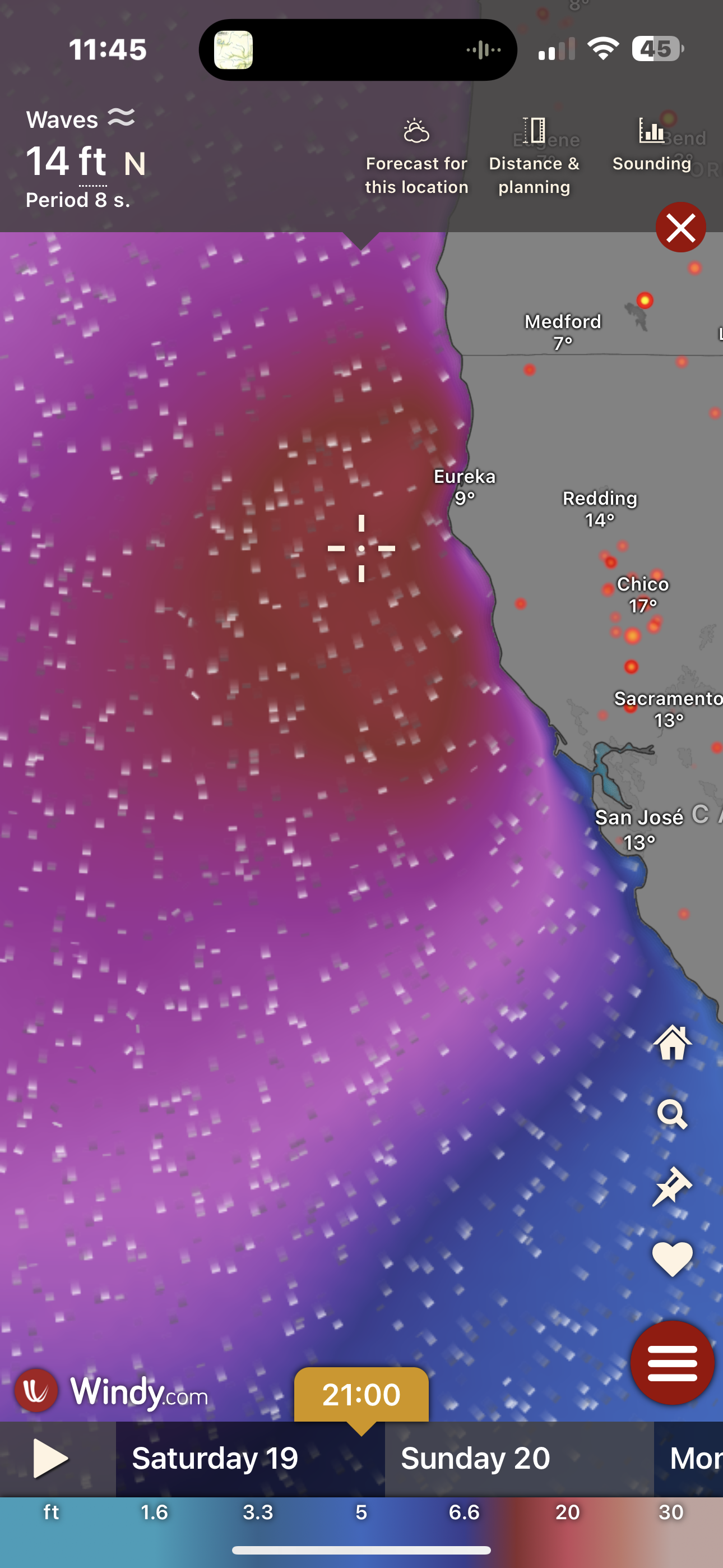

And calm, so calm, Jesse felt up to making breakfast. Its amazing the apatite of a sailor who has shaken off their seasickness. We are staying ahead of the weather at this point, and I’m glad we got south before the 15 knot southerly was forecast for the area.

Happy boat. Chelsea vacuumed. Tight ship.

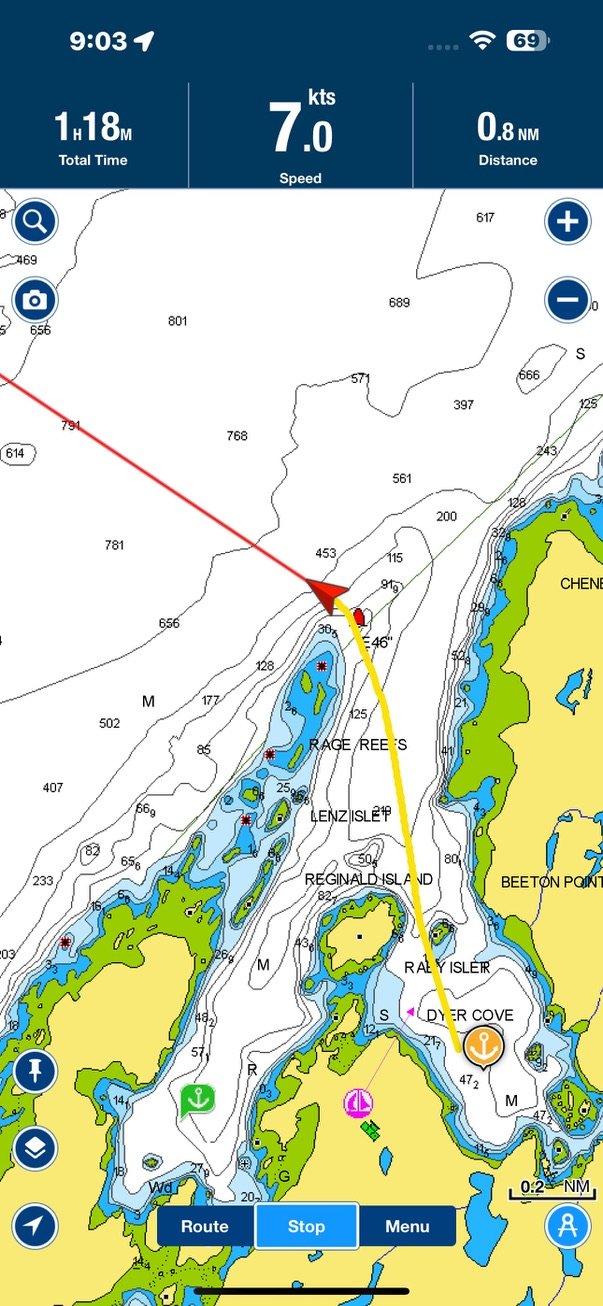

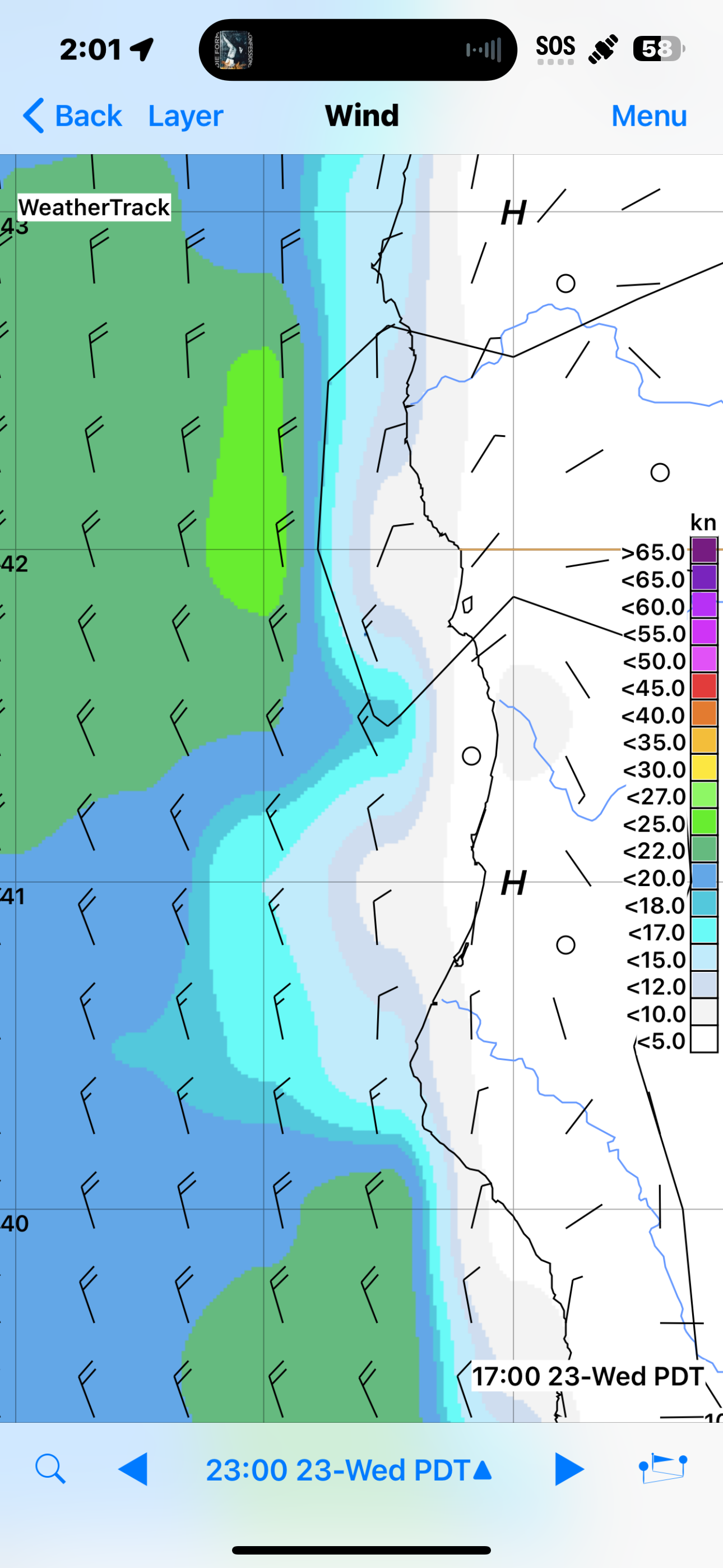

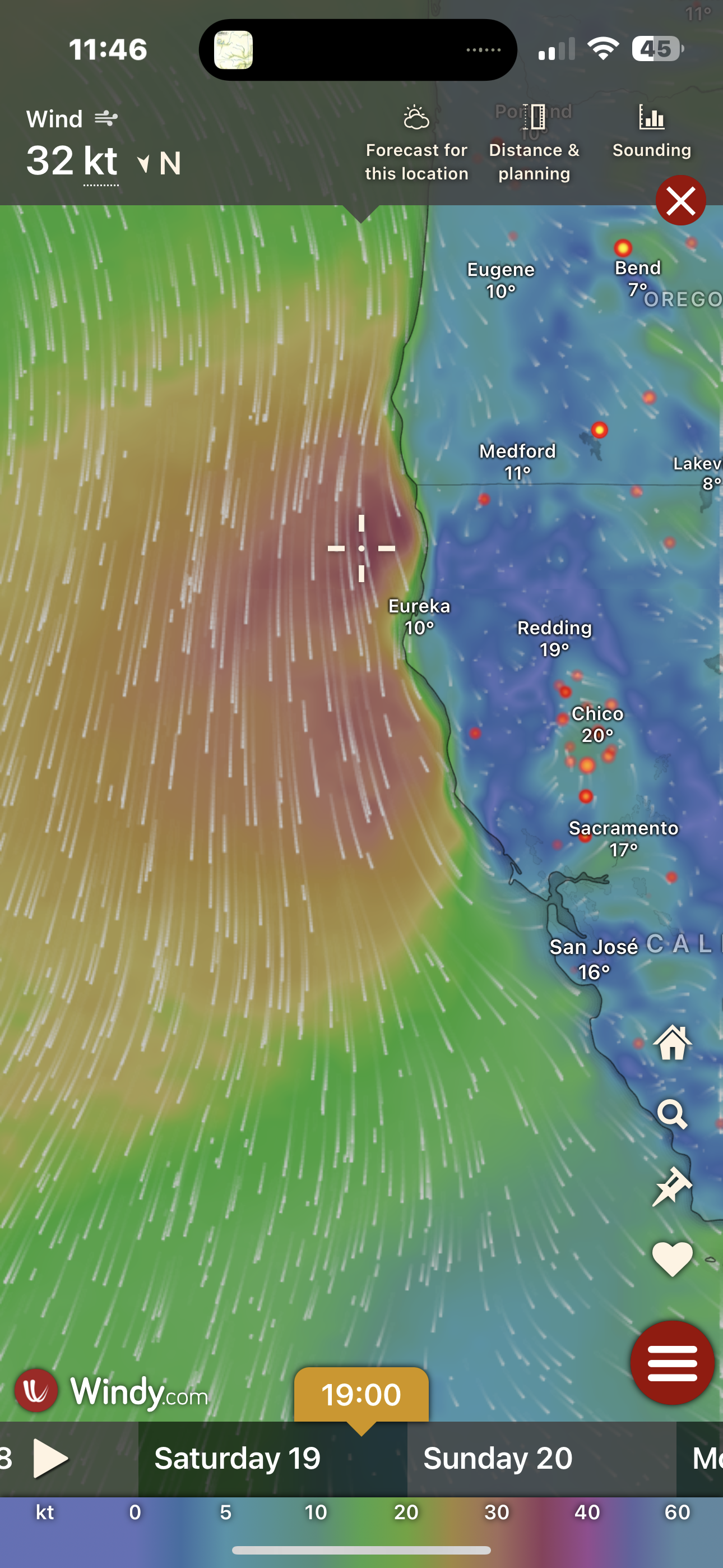

Looks like 20 plus NNW by midnight for rounding Cape Mendocino. Headed straight for Eureka to set up the broad reach out and be ready for the 25 knots there, but nothing but rolling so far.

Tried to sail and gave up

Day 6

Wind filled to 30 for a bit on the last watch, and the main got loose. Inmast furling requires a mandrel inside the mast and a system where, while the outhaul is pulling the sail out, a furling line controls this unfurling. There is an auto-release in the system if it loads up too much, where, if reefed, it will undo and furl out. There is an additional locking device on this system. Unfortunately you have to go to the mast to do it, which in my mind almost cancels out the advantage of and inmast furling system where its main virtue is that can be “furled from the cockpit”

Beautiful conditions for entering the bay.

Got in before happy hour ended. Perfect.